STOMA GmbH

Continuous further development and intensive research ensure that STOMA etching machines are among the most modern and robust devices on the market today. These machines impress with their exceptionally high quality as well as their solid and robust construction, which reliably withstands the demanding requirements of industrial use. Professionals around the world appreciate the durable design and precise workmanship that ensures consistently excellent results. This combination of technological progress, proven stability and consistent quality control makes STOMA etching machines a reliable choice for users in a wide range of industries.

Our services

STOMA stands for high-quality machines and agricultural products that are precisely tailored to your requirements. In addition, we offer comprehensive services such as commissioning, hall planning, practical training and a reliable spare parts service. Together, we ensure efficient processes, maximum productivity and sustainable success - in every sector and every area of application.

STOMA etching machines

STOMA etching machines are specially designed to produce stamping dies made of magnesium, zinc, copper and steel precisely and efficiently. Thanks to state-of-the-art technology, they achieve maximum accuracy in etching and enable the production of dies for a wide range of applications and industries.

The robust design made of high-quality materials guarantees maximum reliability and a long service life - a decisive advantage for demanding production processes.

Whether filigree engravings or complex embossing forms: With STOMA etching machines, you create a perfect basis for a wide range of embossing processes and ensure consistently high quality for your embossing dies.

STOMA plate shears

The plate shears from STOMA are equipped with two extremely robust blades made of high-alloy special steel. The fixed lower blade and the precise, electrically driven upper blade enable clean, precise cuts. High-quality, generously dimensioned welded constructions and backlash-free bronze round guides guarantee long-lasting, low-maintenance operation.

An adjustable front and side stop ensures exact cut-off lengths, while the automatic hold-down device reliably ensures dimensional accuracy. The optimized table adjustment and height compensation for the bottom blade also make regrinding and setting the cutting gap easier. A powerful worm gear motor with maintenance-free eccentric drive transmits the cutting force precisely and ensures consistently high cutting quality.

STOMA agricultural products

STOMA's agricultural products are the result of consistent research and continuous development. They have been specifically tailored to the individual requirements of modern agricultural and horticultural businesses and therefore offer practical support for a wide range of applications. Thanks to their robust, durable design, they are ideally suited for use both outdoors and in greenhouses.

Thanks to high-quality materials and precise workmanship, STOMA agricultural products guarantee high reliability and a long service life. They help to make work processes more efficient, secure yields and conserve resources. Users benefit from a sustainable, future-oriented solution for professional plant cultivation.

Our services

We provide you with reliable support when commissioning your machines so that your production can start quickly and smoothly. Our precisely created hall plans with optimum machine positioning and integrated cable connections ensure perfect processes.

We provide practical training to make your team fit to handle the machines safely and efficiently. In addition, our spare parts service guarantees a fast supply of high-quality spare parts and thus ensures the trouble-free operation of your systems in the long term.

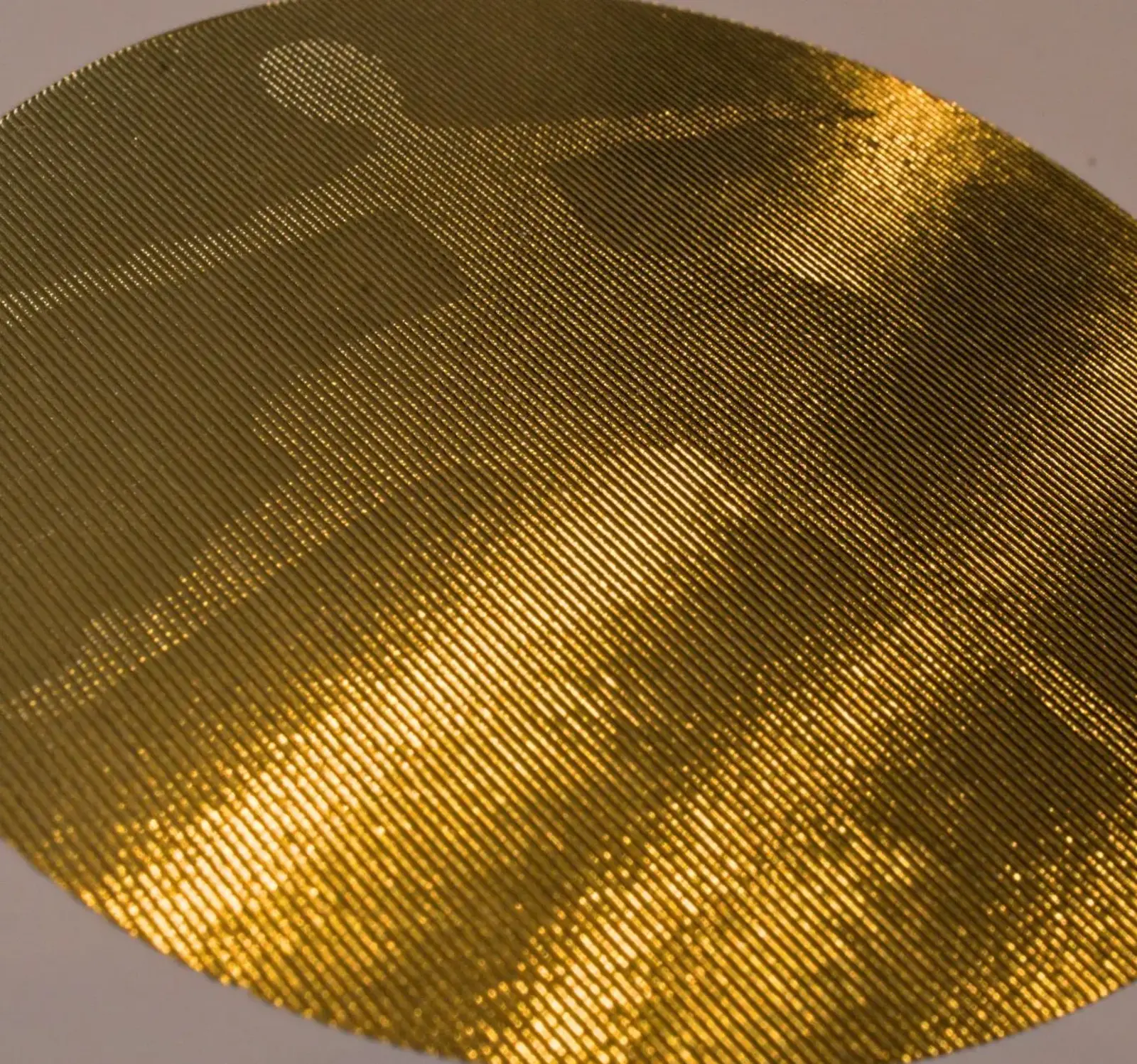

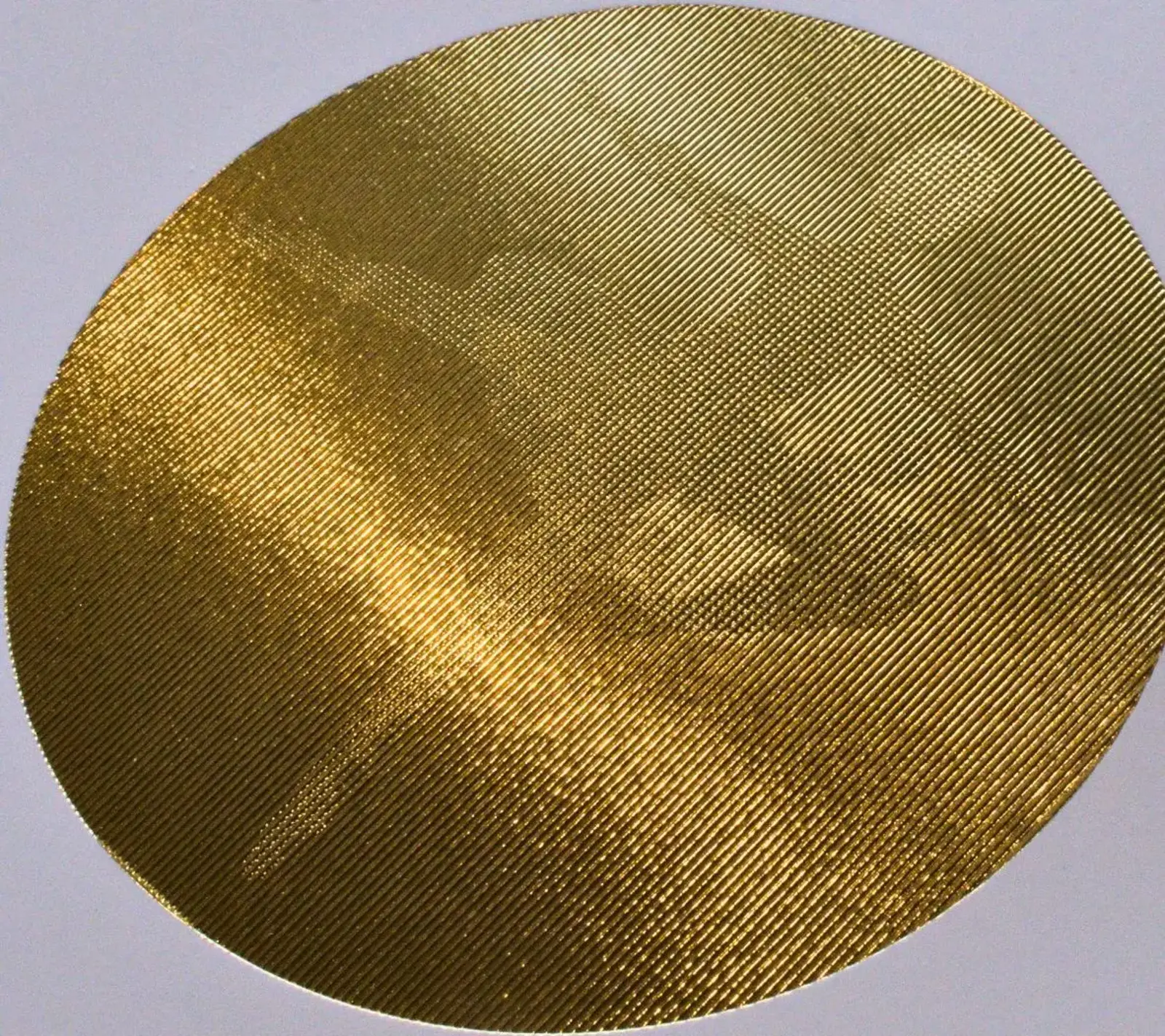

EAZYGRAM - The new embossing technology from STOMA

With EAZYGRAM, STOMA presents an innovative solution for hologram printing: A magnesium cliché produced in a one-step etching process enables the creation of impressive holographic effects - such as lenticular or flip-flop effects - with conventional hot stamping foil.

Ideal for security printing and all applications that require visually striking and forgery-proof elements.

Your benefits at a glance:

- Up to 70 % cost savings compared to conventional hologram processes

- Up to 4 motifs can be realized in a single embossing process

- No special foils required

- Easy integration into existing embossing processes

EAZYGRAM - Holographic effects, rethought.